News

Designing

WE CAN’T doesn’t exist for us – we undertake executing even the hardest tasks.

Meeting expectations of modern manufacturing, our experienced staff or engineers, constructors and technologists will help you to design a product that will fit your expectations.

You will receive a complex service: from an idea to ready ready-made product.

We use the latest engineering devices, that help to design and optimize project and let to get the best ratio between quality, efficiency and cost of production.

Haven’t you found a product that will fit your needs – contact us. We’re open to new challenges so we’ll make it for you.

Water jet cutting

Water jet cutting (aka abrasive blasting, hydro-abrasive machining) in other words is an usage of water stream with extreme high pressure in aim to cut material with thickness less than 200 mm. Table for material processing has dimensions 1,5x3m.

It gives possibility for cutting large elements or few simultaneously. When soft and thin materials are cut, only water is sufficient enough but when material is harder and thicker, using water with garnet is necessary. This is done in a such way, that water accelerates garnet to speed close to the speed of sound (340,3 m/s), which is responsible for the incredible precision that water cutting technology guarantees. The garnet itself can be compared to sand except that it is considerably harder and has a much sharper edge.

Cutting all materials with water.

Water jet cutting gives possibility of cutting with precision up to 0,1 mm materials like:

-natural stone and conglomeration

-carbon steel

-stainless steel

-coloured metal and coloured metals alloys

-glass and polycarbonate

-ceramics

-gres

-rubber and synthetics/plastics

-wood and wood-based materials

-other materials? Call us! We will do samples of untypical material for free

Waterjet cutting is an innovative technology using water stream with extremely high pressure in aim to cutting all kinds of materials from stone to metals to glass, wood or plastics. The key advantage is that there is no thermal effect on the material being cut.

Water jet has no equal in comparison to other methods of cutting. Above all, stream of water cuts materials that are significantly thicker than those which could be cut by laser or plasma.

Apart from that executed processing is characterised by distinct precision comparing to other methods.

In addition, material is not subjected to influence of high temperature as it is in thermal cut. Thanks to this cut raw material is not liable to mechanical damages like scratches or crizzles.

Waterjet cut has a lot of advantages, the most important are enlisted below:

- can cut virtually all types of materials

- high quality of cut edges

- lack of influence of surface structure of material what eliminates need of finishing processing

- execution of any shapes

- environmentally-friendly technology – there is no any harmful fumes or dangerous waste made during processing

- instant and efficient processing of raw material

We own only highly specialistic equipment – the WJS X3015 which allows us to waterjet cut materials up to 200 mm thick. Our table, used to process parts, has dimensions of 3×1,5 m. This gives us the ability to cut large parts or several at the same time with water.

Being aware of the complexity of materials and raw materials, we take an individual approach to each ordered water-wear machining service and the orders we carry out are accurate, efficient and reliable. In order to meet the needs of our customers, we are open to any suggestions, also willing to share our experience.

We offer structural and stainless steel cutting services using a numerically controlled machine.

Plasma cutting

Plasma cutting method is characterized by:

– minimal influence on the structure of material, that results from very narrow cutting zone and mild heating

– small cutting gap and low loss of material

– smooth edges and good quality of surface

Our plasma cutting machine lets to cut sheet metal with thickness up to 30 mm and maximal dimensions of element are 1500 mm by 3000 mm.

We cut sheet metals made-to-measure and cut any details according to given projects. We also cut (with plasma method) perforations in pipes up to Ø620×25.

We work on our own or customer’s material.

CNC milling

Biggest advantages of our CNC milling:

– We use advanced cutting tools to ensure highest performance, quality and aesthetics od produced parts (it has particular meaning when producing aluminium parts which are anodised next)

– Our machine park is consist of precise and reliable machine tools made by reputable companies like DOOSAN and MIKRON

– We execute instrumentation on our own thanks to what we limit the costs and time of service realisation

-We give advice to our clients to improve cost-efficiency of production of parts milled with CNC

-Experienced team of specialists guarantees professional service of CNC milling to our clients

– We use modern measuring and control instruments including measuring arm by HEXAGON

Materials we process

– aluminium

– steel

– high-carbon steel

– copper

– brass

– stainless steel

– titanium

Maximal dimensions of processed materials: 1300x670x600 mm, weight up to 1000 kg

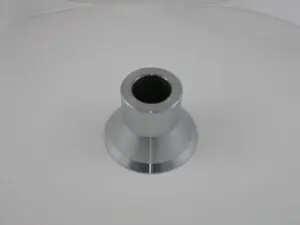

CNC lathework

The biggest advantages of our CNC lathework:

– we use the most modern cutting tools to maintain/keep highest quality of performance of CNC lathework

– we work on precise and infallible turning centres by DOOSAN

– we use proper means of measurement including measuring arm by HEXAGON to be entirely sure about dimensions’ accuracy

– we lathe parts with tolerances about 0,02 mm – precise, serial processing is our specialty

– we command with experienced team of specialists what guarantees professional service of every order

– we conduct Statistic Control of Process integrated with measuring devices

Materials we process:

– aluminium

– steel

– high-carbon steel

– copper

– brass

– stainless steel

– titanium

We process:

– forging

– casting

– rods with diameter up to 750 mm and next processed in a fixture

Welding

Welding with TIG, MIG/MAG (with PULS function) of carbon steel and acid-resistant

Welding services executed in our plant are not only guarantee of quality and durability but safety, too. Clients for whom we weld different kinds of elements are sure that they are durable and will not resolve under influence of mechanical powers. They are executed according to any rules and safety norms and they are supervised by coordinator. We execute orders according to client’s documentation or we prepare it ourselves if project demands.

Welding services have it right that the most crucial component conditioning high quality is the steady hand of a good specialist. Both TIG and MIG/MAG welding in our company are carried out by highly experienced employees who continually improve their capabilities by attending courses to raise their qualifications.

Leakage testing of fittings

Equipment we use for tests

Ventil VCB30-L is a complete solution for testing shut-off valves in vertical position, compatible with majority of international testing standards. The fixing system allows the body and seat to be tested with the outlet flange open for visual inspection. This universal test table can be used for post-repair testing of valves by service companies, but can also be used by manufacturers.

Main characteristics:

Range 1/2 – 16 inches / DN15 – 400 mm

Testing with gas 0 – 7 bar / 100 psi

Testing with fluid 0 – 400 bar / 5,800 psi

Painting

Our speciality is spray-painting with a gun using the hydrodynamic (electrostatic) method. Our company has a paint shop where we paint all types of machine components and fittings. We accept both large and small orders. We carry out spray painting assignments for individual customers and institutions. We guarantee perfect paint coverage for each order.

We offer:

– painting of surfaces, even those of irregular form

– thorough coverage of the entire surface of steel structures

– high efficiency and low service costs

– high effectiveness and corrosion protection

– dust-free painting process

We have professional equipment that allows us to cover any surface quickly and efficiently, as well as expert staff who have the necessary qualifications and competences. We take care to provide the best possible performance for every steel structure painting service we are commissioned to provide, ensuring accuracy, thoroughness and efficiency.

The prices of the services depend on several factors, such as the size of the structure, the type of work, the colour of the paint, the conditions of the order or the type of element itself. On the basis of this information, we provide the customer with a quotation and agree the details of the order.

Maximum size of painted elements Ø600×500 mm 300 kg

Automation

Automation of products and whole manufacturing process are one of the most important aspects of modern enterprise. Automation helps to make steering of fittings more precise and safe. It ensures possibility of coordination of all process and in result leads to improve their quality or to generate savings.

Our offer consists of wide range of solutions we can offer to you to automatise working of our products. We use only assortments of proven producers e.g.:

– electric actuators by AUMA, ROTORK, BERNARD CONTROLS, MODACT, VALPES

– pneumatic actuators by AIR TORQUE, PRISMA

– limit switches by ROTECH

– positioners by SIEMENS

– manual gears for fittings steering by PRO-GEAR

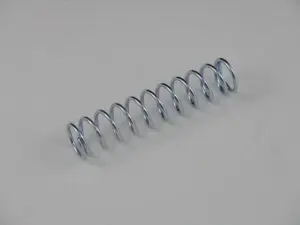

Regeneration

We execute service of ball valves regeneration made by Andrex and other manufacturers.

Range of works:

– diagnostics of problem

– dismantling

– replacement of sealing

– polishing, running pressing element in

– filling

– mantling

– leakage tests

– painting

Galvanising services

Galvanising

The galvanising services we offer consist of applying the zinc coating using the electrolytic method, giving us a high quality and variety of coatings applied.

We offer galvainising in colors below:

- yellow

- blue

- white

- black

- olive

The main purpose of galvanising is long-lasting corrosion protection giving galvanised parts an excellent appearance. Maximum dimensions of parts to be galvanized 2400x800x800 mm (weight up to 80 kg). For small parts, the desired batch size is 20kg (or multiples). We would like to mention that our services guarantee the corrosion resistance of coatings according to the requirements set out by the Polish Standards and DIN. We measure the thickness of coatings using non-destructive methods and also determine adhesion to the substrate. We carry out corrosion resistance measurements in accordance with DIN requirements.

|

|

|

|

|

|

|

|

|

|

|

|

Blueing

|

|

|

|

Sand blasting

Technical chrome plating

Electropolishing

Service

Dependable and most of all fast service is crucial in every industry. Supplying at Andrex you get guarantee that in case of failure of any from products bought in our company, we offer wide range of service: from mobile support to delivery of spare parts to direct repairs on the installation plant or in Andrex workshop. We serve you with advice and fast support every time you need.

Main tasks of our company’s service:

– repairs within guarantee

– first start-up of fittings in the installation

– servicing in aim to extend guarantee

– post-warranty repairs

Powrót

Powrót